Brief Introduction:

Sino Pharmatec is the pioneer supplier of pharmaceutical turnkey plants that provides integrated engineering solution for worldwide pharmaceutical factory such as IV solution, vaccine, solid dosage, oncology,vacutainer, syringe, etc., in compliance with EU GMP, US FDA cGMP, PICS, and WHO GMP.

We provide the most reasonable project design, the high quality equipment and the customized service to different pharmaceutical and medical factories from A to Z for Non-PVC soft bag IV solution, PP bottle IV solution, Glass vial IV solution, Injectable Vial & Ampoule, Syrup, Tablets & Capsules, Vacuum blood collection tube etc.

Sino Pharmatec integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, Sino Pharmatec customizes engineering solutions meticulously for users on:

*Pre-engineering consulting service

*Production process selection

*Equipment model selection and customization

*Installation and commissioning

*Validation of the equipment and process

*Production technology transferring

*Hard and soft documentation

*Training for skilled workers and so on.

1.Non-PVC soft bag IV solution Forming-Filling-Sealing production line:

This line is used to produce IV bag by Non-PVC(PP) film, and finishing bag forming, printing, filling and sealing by the same machine.

The IV bag size ranges from 100ml - 5000ml. Only need half an hour to change from one size to another. It has special design of 130mm width to save film, also can realize 100% film utilization, no any waste material.

2.Sterilizing system:

It is used to sterilize the finished IV bag by superheated water at 121℃. The sterilizing time can range from 15 - 30 minutes according to different production technology requirement, sterilizing temperature is adjustable.

We can equip with automatic IV bag loading and unloading machines, also automatic sterilizing carts conveying system as option.

3.Packing system:

It can finish IV bag drying, leak detection, light inspection, overwrapping and carton packing.

We can equip with automatic shipping carton opening, instruction manual and certificate inserting, carton packing, carton sealing, labeling, data tracing system, and auto rejection system, which can reject the cartons with wrong weight, or the ones with unqualified label.

4.Pharmaceutical water treatment:

It includes purified water treatment (2RO+EDI), water distiller (WFI), and pure steam generator. PW tank and WFI tank is included as well.

5.Solution preparation system:

It is used to mix the medicine with injection water together. We equip with 2 sets of solution preparation tanks, with Mettler-Toledo load cell, and magnetic stirring system.

6.Clean room & HVAC:

It includes clean room wall panels, ceiling panels, windows, doors, flooring, lighting, air handling unit, HEPA filters, air ducts, alarming, auto control system etc. To keep the key IV solution production process protected under Class C + A environment.

7.Black utility

It includes air compressor system and boiler system to supply necessary compressed air and steam for Non-PVC soft bag IV solution production.

8.Laboratory:

It includes all kinds of lab testing instruments, and lab furniture to test the IV bag samples and raw material, such as stability chamber, HPLC, atomic absorption, ultraviolet spectrometer, fourier transform infrared spectrometer etc.

9.Distribution & pipeline system:

It includes all kinds of process pipeline and industrial pipeline needed in Non-PVC IV bag turnkey plant, such as purified water, injection water, pure steam, cooling water, chilled water, compressed air, industrial steam etc.

* 100% film utilization: no waste edge between every two IV bags, reducing both material and energy consumption.

* Reliable heating and welding system: Make sure the leakage rate for IV bags less than 0.03%.

* Quick changeover: Only need 0.5-1 hour to switch from one IV bag size to another.

* Compact structure, reduce 1/3 length of the machine, save room space and running cost.

* Stable running and transmission system: use combo-port design, only need 1 control system, 1 HMI and 1 operator.

* Safe filling nozzle: Adopt patent contact filling, no solution overflows, no particles generation during IV bag filling process.

* Auto detection and faulty rejection system to reject the unqualified IV bags automatically after cap welding.

Cost saving of Sino Pharmatec patent designed IV bags:

a.Special IV bag design with width of 130mm, one IV bag can save 10mm film than other suppliers.

b.No wasted edge between IV bags and groups, 100% film utilization.

c.Can save 250 iv bags more per roll of film than others with width of 135mm

Sino Pharmatec have a very professional technical and engineering team, our onsite training and after-sales support can give long term technical assurance for your NON-PVC IV fluid turnkey plant:

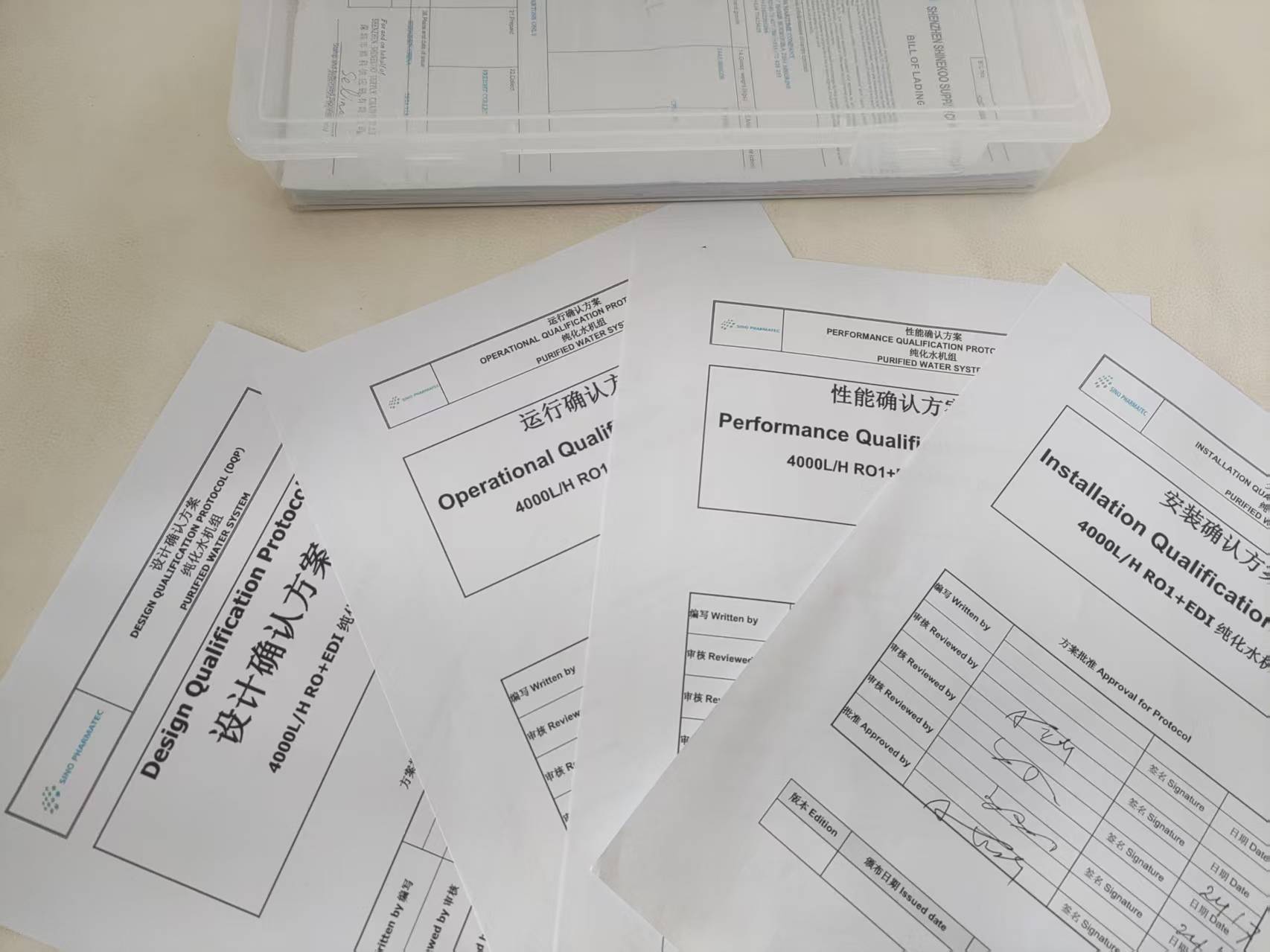

Sino Pharmatec Full range of documentation can help you get GMP & FDA certificate for your IV fluid plant easily(Including IQ / OQ / PQ / DQ / FAT / SAT etc both in English and Chinese version):

Sino Pharmatec profession and experience can help you finish whole IV solution turnkey plant in the shortest time and avoid all kinds of potential risks:

Meanwhile, we helped our customers to built 10+ pharmaceutical and medical turnkey plants.

| Item | Main Content | ||||||||

| Model | SRD1A | SRD2A | SRS2A | SRD3A | SRD4A | SRS4A | SRD6A | SRD12A | |

| Actual Production Capacity | 100ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 |

| 250ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 | |

| 500ML | 900 | 2000 | 2000 | 2800 | 3600 | 3600 | 5000 | 8000 | |

| 1000ML | 800 | 1600 | 1600 | 2200 | 3000 | 3000 | 4500 | 7500 | |

| Power Source | 3 Phase 380V 50Hz | ||||||||

| Power | 8KW | 22KW | 22KW | 26KW | 32KW | 28KW | 32KW | 60KW | |

| Compressed Air Pressure | Dry and oil-free compressed air, the cleaness is 5um,the pressure is over 0.6Mpa.The machine will automatically warn and stop when the pressure is too low | ||||||||

| Compressed Air Consumption | 1000L/mim | 2000L/mim | 2200L/mim | 2500L/mim | 3000L/mim | 3800L/mim | 4000L/mim | 7000L/mim | |

| Clean Air Pressure | The pressure of clean compressed air is over 0.4Mpa, the cleaness is 0.22um | ||||||||

| Clean Air Consumption | 500L/min | 800L/min | 600L/min | 900L/min | 1000L/min | 1000L/min | 1200L/min | 2000L/min | |

| Cooling Water Pressure | >0.5kgf/cm2 (50kpa) | ||||||||

| Cooling Water Consumption | 100L/H | 300L/H | 100L/H | 350L/H | 500L/H | 250L/H | 400L/H | 800L/H | |

| Nitrogen Consumption | According to the customer's special requirements, we can use the nitrogen to protect the machine, the pressure is 0.6Mpa. The consumption is less than 45L/min | ||||||||

| Running Noise | <75dB | ||||||||

| Room requirements | Temperature of the environment should ≤26℃, the humidity: 45%-65%, Max. humidity should less than 85% | ||||||||

| Overall Size | 3.26x2.0x2.1m | 4.72x2.6x2.1m | 8x2.97x2.1m | 5.52x2.7x2.1m | 6.92x2.6x2.1m | 11.8x2.97x2.1m | 8.97x2.7x2.25m | 8.97x4.65x2.25m | |

| Weight | 3T | 4T | 6T | 5T | 6T | 10T | 8T | 12T | |

Contact: Support team

Phone: +86-13818385401

E-mail: support@pharmatec-gmp.com

Add: 6th Floor, No. 615, Ning Qiao Road, Shanghai, China